Differential temperature furnace are mainly used for differential temperature treatment of workpieces such as rollers, especially the quenching of large rollers. It can heat up the rollers quickly to a certain thickness below the surface. Surface temperature of the rollers can reach the quenching temperature quickly while the temperature inside the roll still keeps low. So the workpiece can get different microstructures inside and outside, which can ensure the rigidity of the rollers working surface and also ensure the strength and temper of the whole rollers. It can save energy enormously in this heat treatment process of rollers.

Differential temperature furnace is of horizontally opening-closing type. It mainly includes the furnace body, the driving mechanism to open or close the furnace body, the burning device, the air and gas supplying system, the roll revolving and supporting devices, the burning autocontrol system, the control systems for opening or closing the furnace body and revolving the rollers and so on.

The fuel of this type of furnace is coal gas or natural gas. We use PLC and host computer to monitor and control the proportion of air and gas for combustion, so the operation of the whole system is convenient, safe, highly efficient, steady and energy saving.

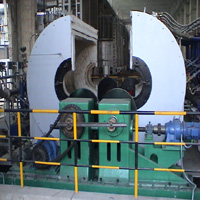

Roll surface quenching units

The spray quenching device includes two groups of supporting rollers that can move and rotate, and two sets of sprayers. The supporting rollers are used to support and revolve the rollers for the surface quenching. The two sprayers are installed on both sides of the supporting roller to spray the cooling medium. Through controlling the spray pressure, flow, time and angle of cooling medium, the uniformity in roll surface rigidity can be ensured.

Two supporting rollers are made of 45# cast steel. Every supporting roller body is welded with axle heads. The body surface has two shaft shoulders on both ends and has tapezoidal drainage slots with certain depth. Shaft shoulders can avoid the quenched rollers being threw out accidentally. The revolving speed of supporting rollers is 9r/min and the rollers can revolve clockwise or counterclockwise. Bearing seat is cooled by water to improve its working condition. Dependable measures are taken for heat insulation of the reducer, motor and drive chain to improve the service life.

There are two sprayers, which include spray vehicles and mist pipelines. It can spray water and mist by one nozzle. Each spray vehicle has a row of nozzles and the nozzlesí» angle and height can be regulated to reach the perfect quenching effect. Every nozzle is controlled independently to fit the rollers' length. The forcing air piping and water supply piping systems of the sprayers are configured according to related professional requests. The pressure of supply water is 0.4MPa, the pressure of air supply is 0.6Mpa. The consumption of water and air is determined by technical calculations.