Energy-saving regenerative combustion technology

Energy-saving regenerative combustion technology

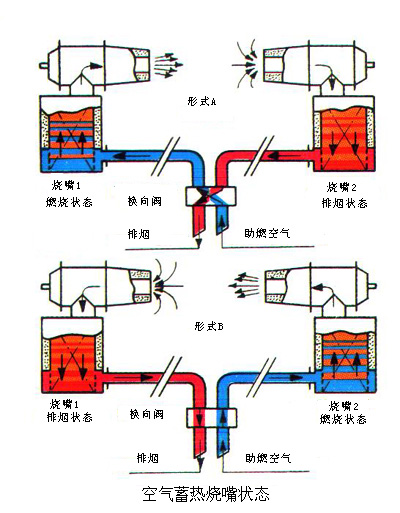

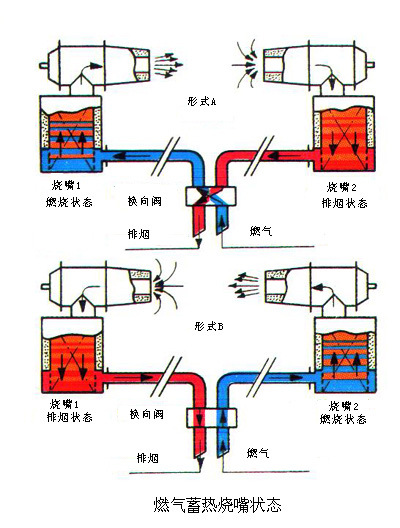

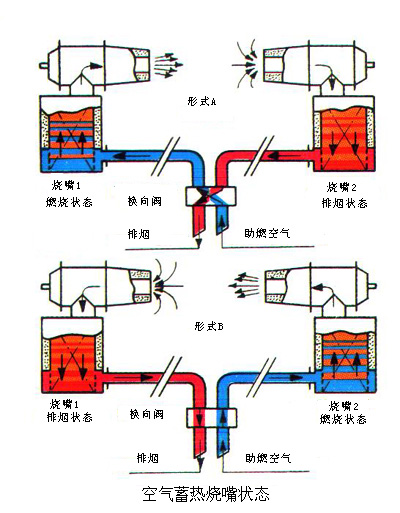

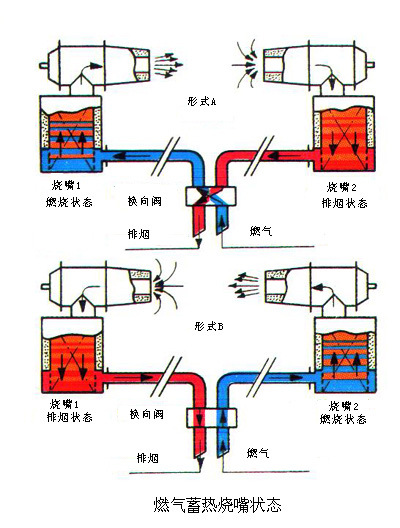

The working principle of regenerative burner is as shown below. The normal temperature air is sent by the fan into the regenerative burner B through a switch valve and heated up when passing through it, with temperature approaching the hearth temperature (usually about 50¡«100¡ælower than the hearth temperature) in a very short time. After the air at a high temperature gets into the hearth, because of mixing with the flue gases in the hearth, it forms an airflow which is rarefied, oxygen-diluted and at high temperature and whose oxygen content is much lower than 21%. At the same time the fuel (fule oil or gas) is injected into the formed airflow and the fuel burns in the little oxygen condition (2~20%). Meanwhile, the hot flue gases burning in the hearth stores the heat energy in the burner A when it passes through it, and then the flue gases whose temperature is lower than 150¡æ is removed through the switch valve. The switch valve which can change the flow direction at not very high working temperature switches with a stated frequency, and it makes two burners working alternatively for store-up and release of heat, so as to save energy and reduce the quantity of NOX discharge. The switch cycle in common use is 30~200s. Energy-saving regenerative technology can be used for many types of furnaces, such as Bogie hearth furnace, Walking furnace, Pusher type furnace, Chamber furnace, Rotary hearth furnace and so on.

Regenerative reheating furnace for large forged pieces

(1) Workpieces to be heated: Large forged pieces

(2) Heating temperature: 1250¡æ

(3) Fuel type: Natural gas

(4) Combustion heat value: Qd=8400¡Á4.18kj/m3

(5) Furnace type: arc vault

(6) Manner of charging and discharging: bogie

(7) Manner of flue gas exhausting: Exhaust the flue gases from the one end of the furnace

(8) Exhaust flue gas temperature: ¡´150¡æ

(9) Temperature of preheated air: ¡µ800¡æ

(10) Average consumption of fuel: ¡´60m3/h

(11) Average thermal efficiency of furnace: ¡´48.5% |